How do I know Balco tyre equipment is tough?

Spiderfrog is an innovative measuring device, which is certified in Germany by Staatliche Materialprüfungsanstalt (MPA), Darmstadt, a company credited by DaKKs, the national accreditation body of the Federal Republic of Germany.

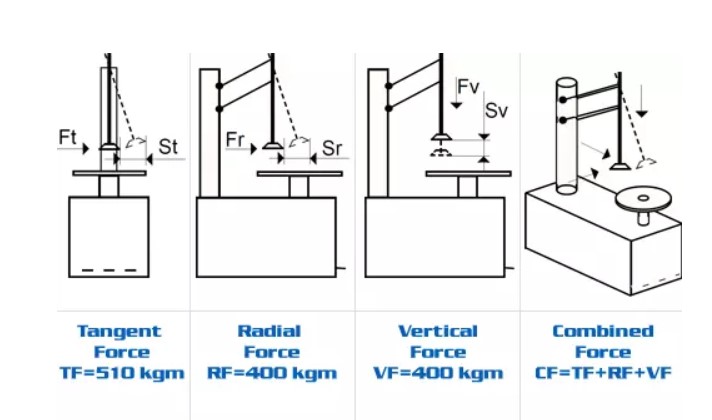

Spiderfrog has been specially designed by Giuliano Group, the manufacturer of Balco, in order to check and measure bending and torsion of a tyre changer’s main parts under stress; which typically occurs during tyre removal and mounting. The stress is created by a combination of forces which are normally generated during tyre rotation, when the tyre changer’s operating arm is engaged and working with tyre and rim, to mount and/or demount the tyre bead over the rim:

- A Tangential Force: Left-to-right or right-to-left

- A Radial Force: Front-to-back and back-to-front

- A Vertical Force: Up/down

Spiderfrog allows you to measure these forces, combine them in a calculated “Combination Force” and find a “Resistance Under Stress Coefficient” (RUSC), which gives an indication of how robust a tyre changer is, in terms of strength and power against all the different types of stress encountered during the tyre changing process.

How it works?

SPIDERFROG is clamped on a traditional turntable, with the size of a 16″ rim, and its structure includes electronic measuring systems connected to air operated cylinders, to simulate the main forces (and related stresses) involved in tire mount/demount operations.

Every electronic gauge measures the movement which is given by each single force applied to the tyre changer. Air cylinders have been sized in a proper way to simulate the highest possible power applied on each part of the tire changer, during mount/demount operation.

For example, cylinder connected to Tangential Stress measuring system has a 90mm. diameter, as we have calculated it will develop a max. tangential force of 510 kgm equal to the same max. torque as a 16″ RunFlat tire during its mount/demount operation’s max effort.

Both cylinders connected to Radial Force and Vertical Force, instead, are 75mm. diameter, as they develop a max. radial and vertical torque of 400 kgm again equivalent to the max. torque of a 16″ RunFlat tire during its mount/demount operation’s max effort.